1. Grind the millstone with the oil material and configure the oil material: mix the used oil/new oil with grass powder or wood chips to make the first grinding material

2 Use a wrench to adjust the pressing roller screws on both sides until the material is discharged normally.

3 Use a wrench to adjust the screw of the pressure roller and the gap between the pressure roller and the millstone until the material is discharged normally. (Note: The adjustment gap should not be too large or too small, otherwise the pressure roller and millstone will be damaged).

4 Start the machine and put the oil material into the inlet evenly.

5 Leave the machine oil running for one hour. (The whole grinding process takes one hour)

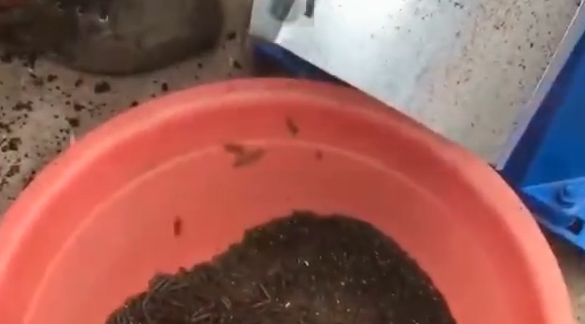

6 Prepare raw materials according to the nutrition required for feeding livestock or poultry (if the moisture is too high, the surface roughness of the particles will be affected and the appearance quality of the particles will be affected. If the moisture is too low, the particles will be soft, the formability will be poor, and the cut-out powder rate will be high. )

7 Start the pellet machine again and slowly pour the powder into the material inlet

8 Adjust the cutter on the edge of the outlet according to actual needs to achieve the length of feed pellets to be cut

9 After the production of feed pellets, start the pellet machine again, and slowly pour in the oil material to maintain the pellet machine for the next use.